PMFHousing currently has three product lines, which are all based on the same basic technology.

Technology

With wood, textile and foam we produce modular elements for the construction of buildings or ready-equipped modular houses, which take up the for centuries proven construction techniques half-timbered house or timber frame construction and sandwich construction “rethought” and develop them further for the current and future requirements.

Thus, the wishes for a safe, stable and valuable building as well as the challenges on the part of ecology and economy are well met:

- Low use of “gray energy,” “cradle to gate” plus Of the entire construction process

- Low energy consumption in the utilization phase of a building with PMF technology.

- Simple and efficient recycling options in the sense of a circular economy, “cradle to cradle” as well as a take-back of the building components we produce.

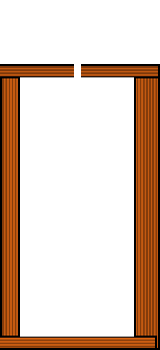

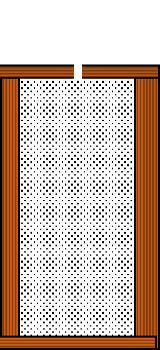

1st step:

The elements for roof – outer wall – floor slab are usually built in the grid 125 cm x 62.5 cm. Depending on the desired architecture, we can use other grid dimensions.

The wood we use has a COC certificate.

1st step:

The elements for roof – outer wall – floor slab are usually built in the grid 125 cm x 62.5 cm. Depending on the desired architecture, we can use other grid dimensions.

The wood we use has a COC certificate.

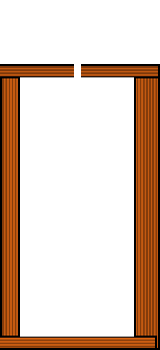

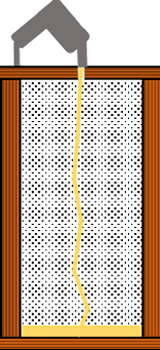

2nd step:

The wooden frame is covered with a three-dimensional textile fabric. This fabric has been developed jointly with the ITA Institute of RWTH Aachen University and the manufacturer PILE Fabrics.

2nd step:

The wooden frame is covered with a three-dimensional textile fabric. This fabric has been developed jointly with the ITA Institute of RWTH Aachen University and the manufacturer PILE Fabrics.

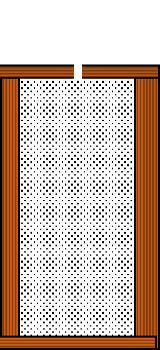

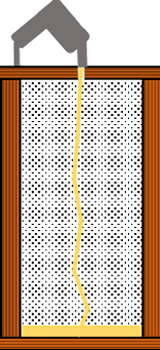

3rd step:

The compartment in the frame is filled and foamed under pressure with a 2-component polyurethane, developed together with BASF.

3rd step:

The compartment in the frame is filled and foamed under pressure with a 2-component polyurethane, developed together with BASF.

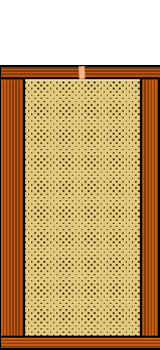

4th step:

The pressure results in a gapless bond between the wood and polyurethane. This enables a statically stable construction element that is impervious to wind and water.

Therefore, PMF technology does not need a vapor barrier outside or inside, which can be violated during construction, installation or repair work, which can cause moisture and mold damage.

The insensitivity to water offers design advantages and avoids water damage in the cavity up to total loss during building use, as is known in practice with blow-in insulation or the use of woolly insulation products.

Since the highly efficient thermal insulation is already integrated in the element, PMF technology allows for thinner outer walls.

On the one hand, this means more living and usable space with the same floor plan compared to otherwise common construction methods.

The highly insulated building envelopes with PMF technology enable technical building equipment (TGA) up to a nearly energy-autonomous building.

We can let our posts protrude outward 2-3 cm beyond the compartment. This facilitates the installation of a facade cladding with wood or carrier plates or the installation of PV modules.

Facing inward, we leave the posts protruding 5-6 cm. This enables the assembly of the technical building equipment (TGA) and saves an additional assembly level.

4th step:

The pressure results in a gapless bond between the wood and polyurethane. This enables a statically stable construction element that is impervious to wind and water.

Therefore, PMF technology does not need a vapor barrier outside or inside, which can be violated during construction, installation or repair work, which can cause moisture and mold damage.

The insensitivity to water offers design advantages and avoids water damage in the cavity up to total loss during building use, as is known in practice with blow-in insulation or the use of woolly insulation products.

Since the highly efficient thermal insulation is already integrated in the element, PMF technology allows for thinner outer walls.

On the one hand, this means more living and usable space with the same floor plan compared to otherwise common construction methods.

The highly insulated building envelopes with PMF technology enable technical building equipment (TGA) up to a nearly energy-autonomous building.

We can let our posts protrude outward 2-3 cm beyond the compartment. This facilitates the installation of a facade cladding with wood or carrier plates or the installation of PV modules.

Facing inward, we leave the posts protruding 5-6 cm. This enables the assembly of the technical building equipment (TGA) and saves an additional assembly level.

PMFVantages:

Moving into a dry house with a healthy living environment

High thermal insulation performance and good summer heat protection

Good resilience to natural disasters such as earthquakes and floods

Assembly on screw foundations to protect substrates

Short construction times due to high degree of prefabrication

Easy to adapt when usage requirements change, necessitating conversions and extensions